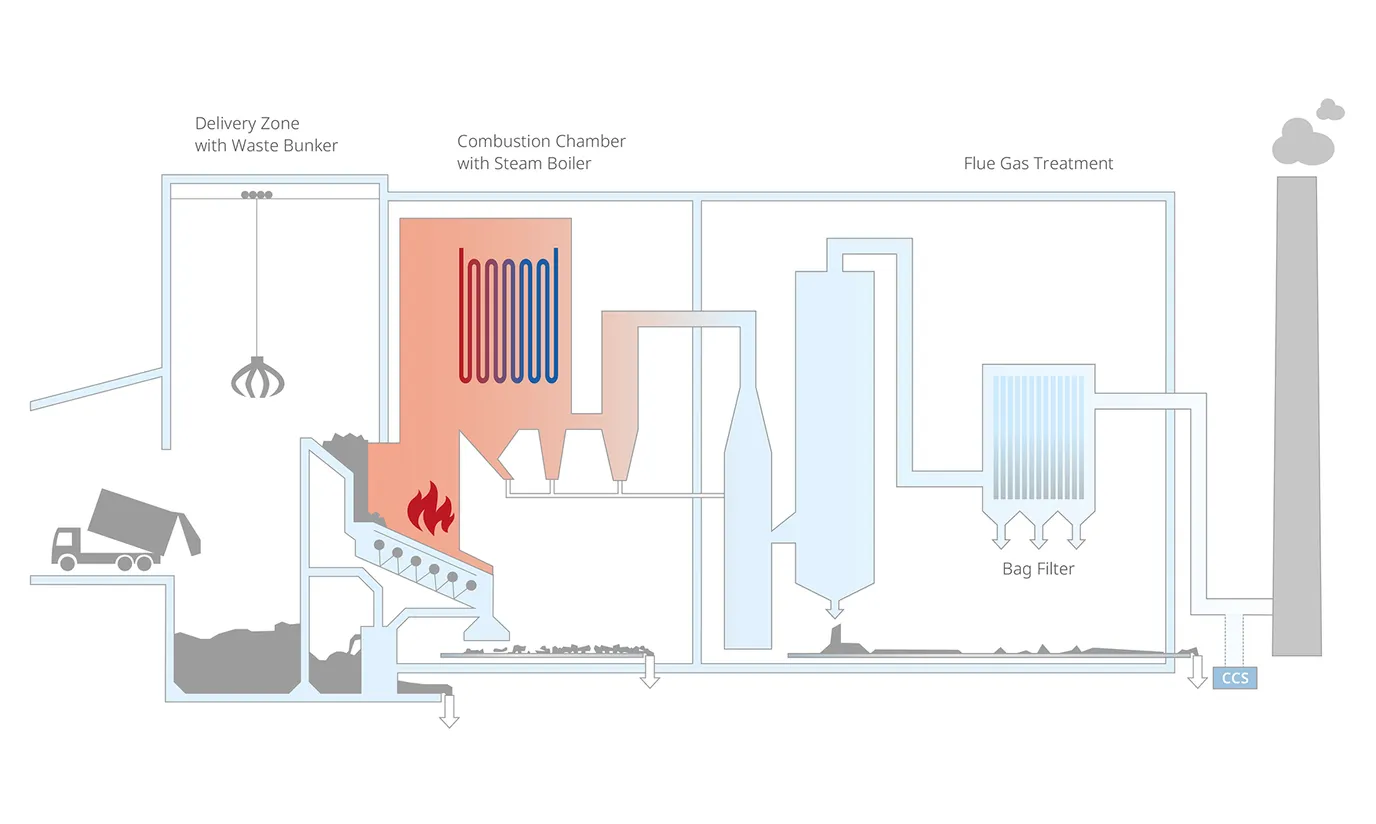

Waste incineration

Solutions for waste incineration

Here you will find an overview of our solutions for waste incineration. Please click on the plus signs in the graphic for more information.

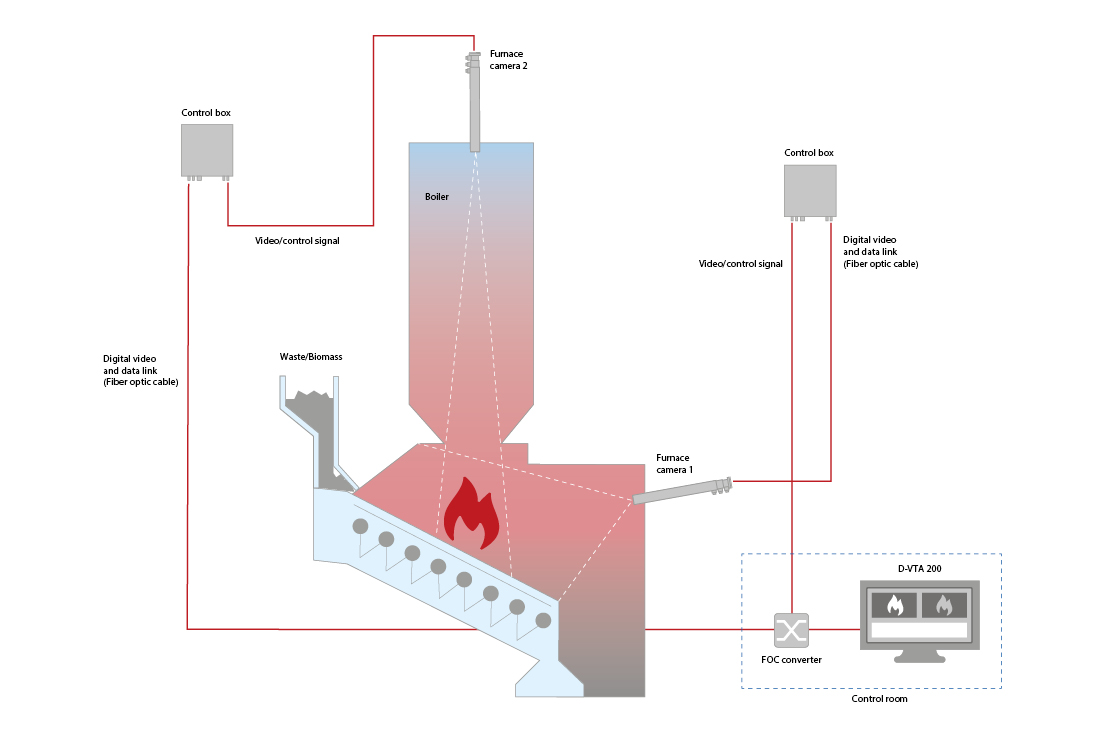

Video and thermography systems

By using video and thermography to monitor combustion, you can ensure optimized SNCR injection and homogeneous burning while minimizing the risk of furnace damage, reducing residues and emissions and optimizing maintenance and operating costs.

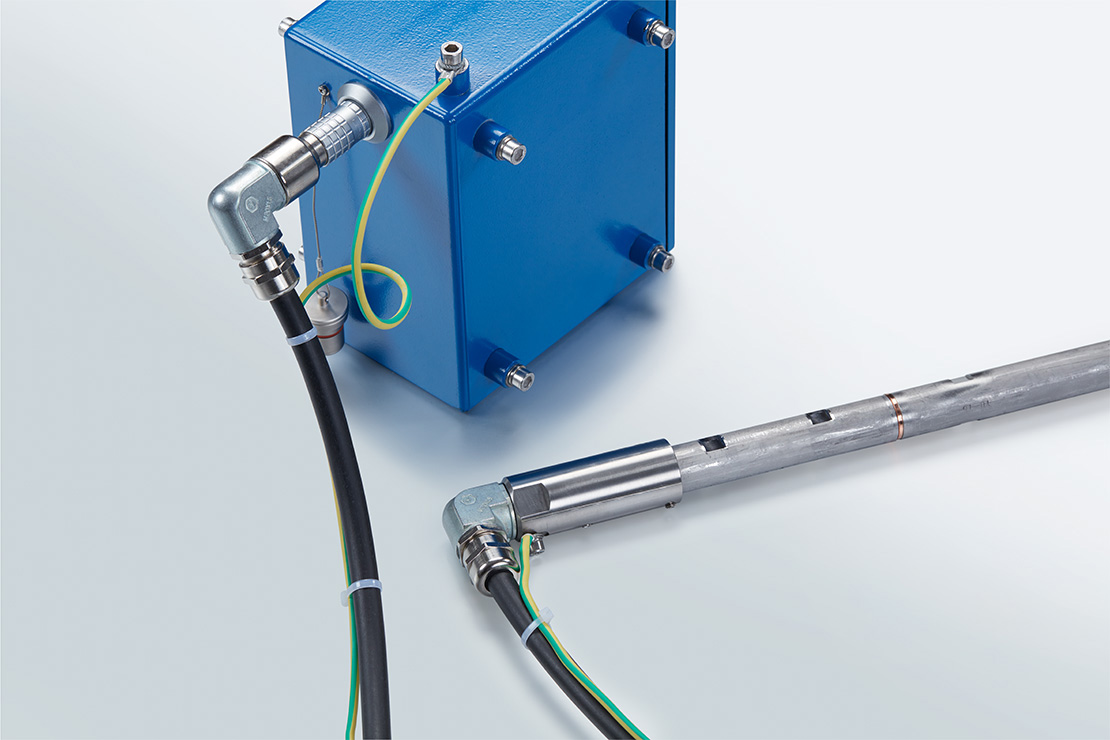

Furnace cameras

Furnace cameras with air or water cooling for visualization of the out burning zone and combustion on the grate. Available a fixed installation or optionally with retraction unit. Offer reliable information on the burning process and its efficiency.

High energy ignition devices

High energy ignition devices eliminate the need for fossil fuels, offering an environmentally friendly ignition solution. They are perfect for very humid and dusty environments and offer easy and economical installation (no fuel train required, low energy consumption).

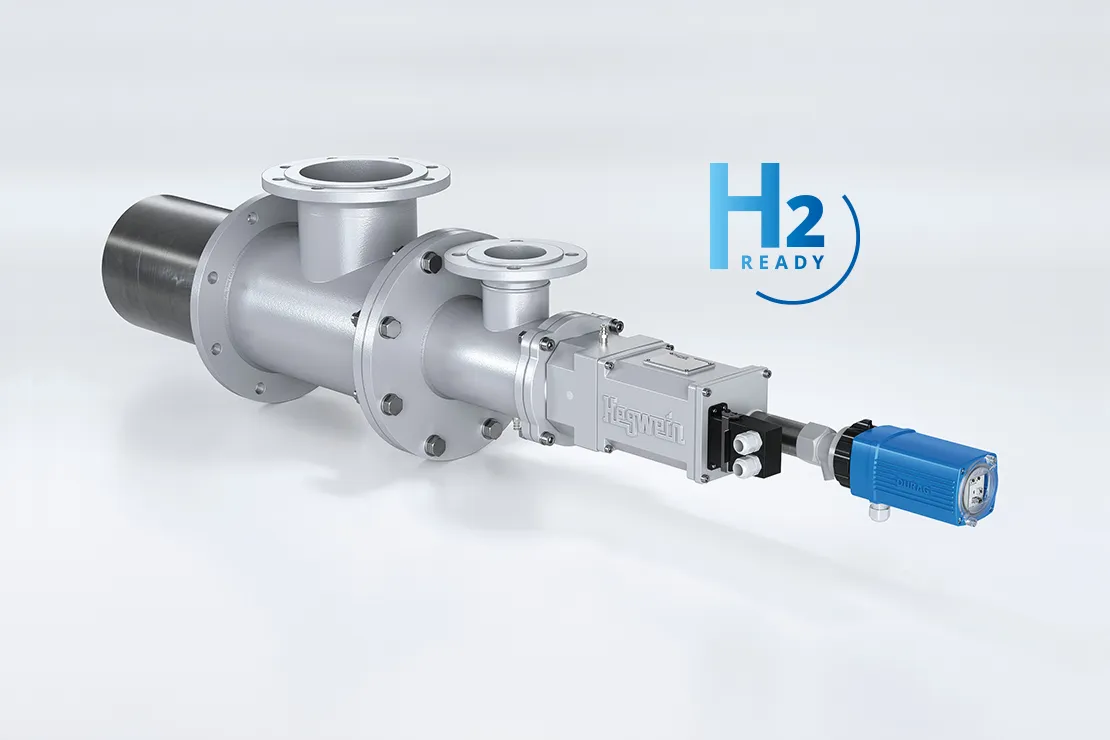

Ignition and pilot burners

Ignition and auxiliary firing for gaseous (including H2) and liquid fuels up to a single burner output of 10 MW. Operating under any conditions, they offer maximum availability for your process. Leveraging advanced engineering, we tailor solutions with proven quality and reliability.

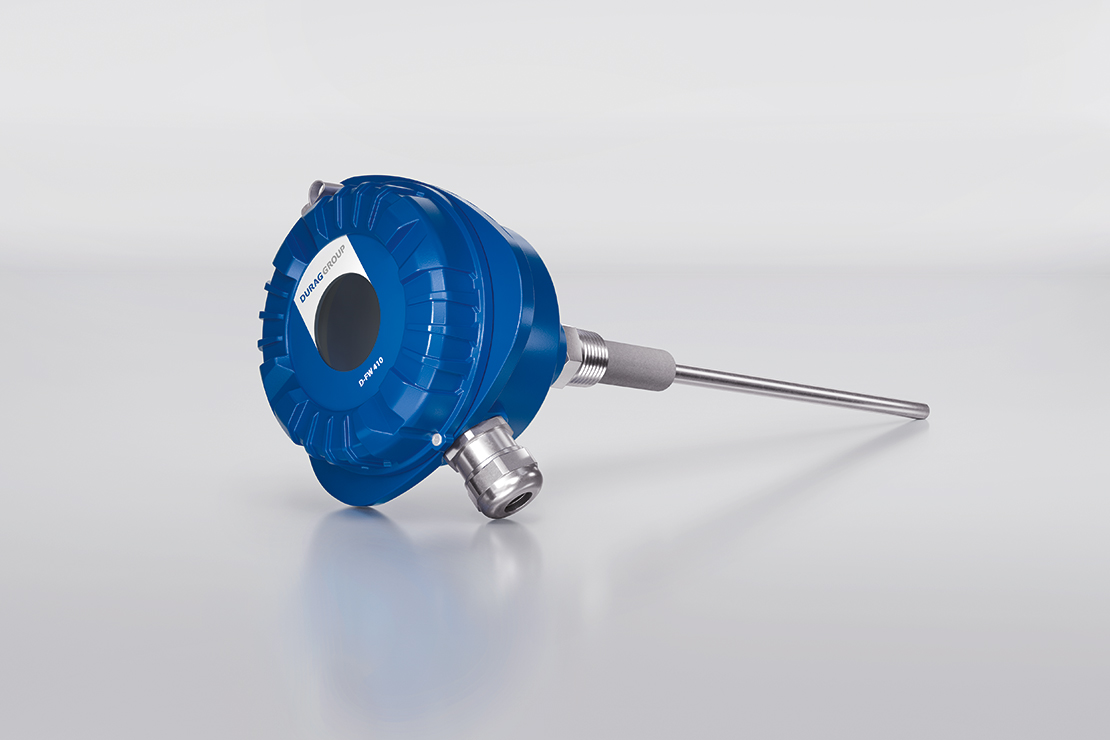

Flame Supervisor

Compact and versatile flame scanner with Auto Learn functionality and intuitive control via the Flame Companion app for effortless operation. Designed for optical flame monitoring across all fuel types and multi-burner configurations.

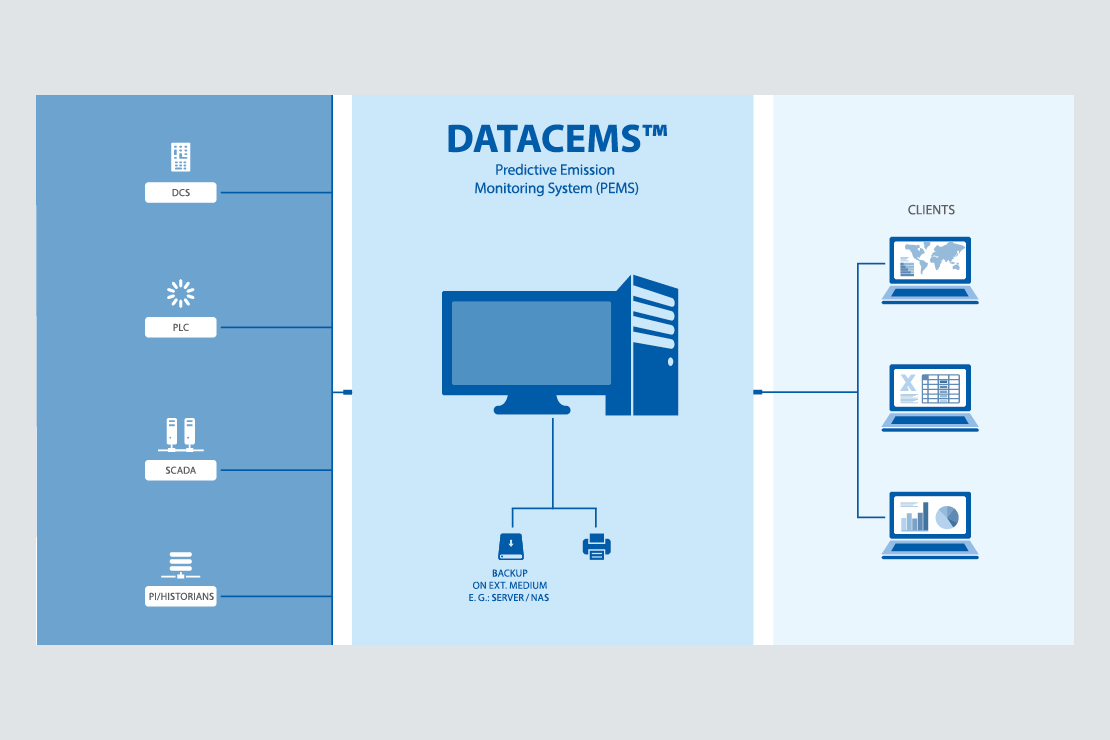

Data acquisition, processing and reporting

D-EMS 2020, one of the world‘s very few certified DAHS systems, ensures precise emission data acquisition, handling and more then regulatory reporting. With real-time value visualization, reports for e. g. legislative compliance and optimized CEMS performance, customers benefit from reduced emissions risk.

Dust and opacity monitors

Monitoring particulate emissions in flue gas streams with DURAG GROUP dust and opacity monitors ensures regulatory compliance, protects the environment and improves operational efficiency. Real-time data enables proactive maintenance, reduces downtimes and promotes sustainable practices for industries.

Flue gas flow measuring systems

Simply measuring the pollutant concentration does not clearly indicate the impact of emissions on the environment. It is important to measure both the composition and concentration of flue gases and their ‘volume flow’ in order to calculate pollutant mass release and determine their total discharge to the atmosphere.

Process and CEMS mercury analyzers

Continuous monitoring of mercury in stack emissions for incinerator operators to meet BAT-AELs and control Hg emissions. Hg process monitoring enables precise adjustment of neutralizer injection, vital in reducing pollutant concentrations and adhering to regulatory standards.

Raw gas, stack emission gas monitors

Certified and approved gas CEMS for compliance with stack emission regulations (ELVs), online monitoring of raw gases for combustion optimization, fuel cost savings and precise adjustment of pollutant absorber/neutralizer injection (SCR, SNCR, DeNOx, FGD) to reduce costs and emissions of pollutants.

Dust filtration performance monitors

Continuous monitoring of filter particulates offers valuable feedback, detecting leaking or broken bags in fabric filters, reducing maintenance time and costs, enhancing emission control and anticipating faults at an early stage for efficient operations.

Dust filtration performance monitors

Continuous monitoring of filter particulates offers valuable feedback, detecting leaking or broken bags in fabric filters, reducing maintenance time and costs, enhancing emission control and anticipating faults at an early stage for efficient operations.

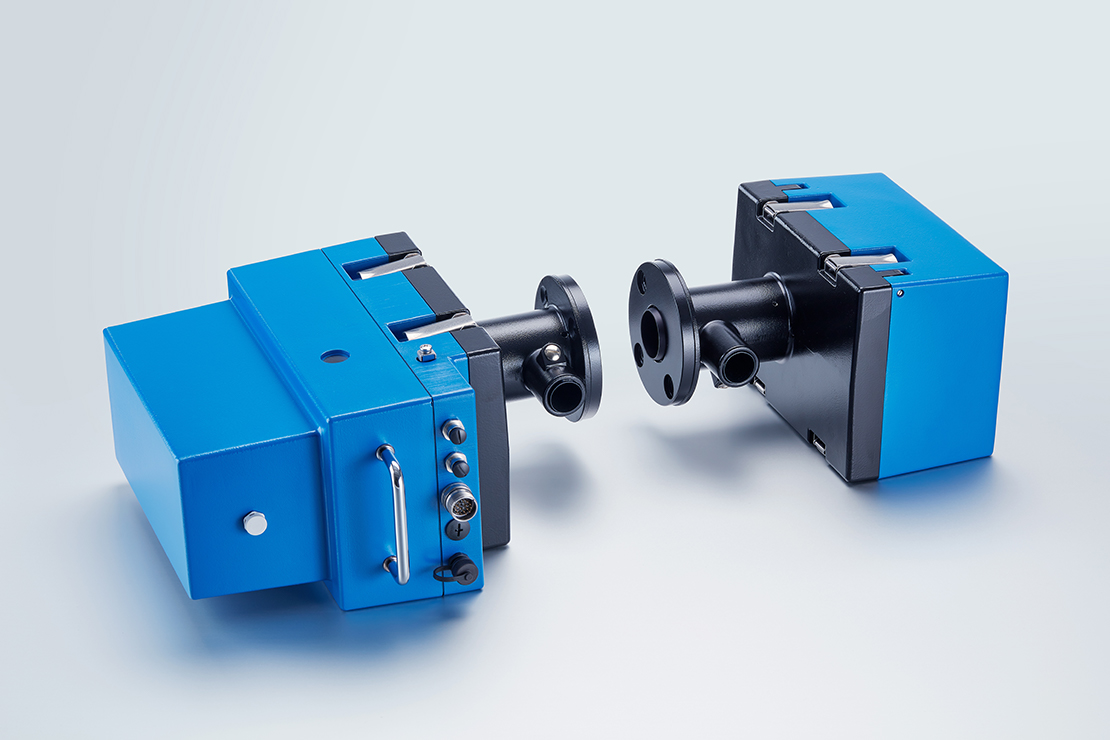

Burner control

Compact self-monitoring and fail-safe burner controllers for gas and oil burners. They ensure safety and efficiency and help you adhere to start-up safety time limits and regulatory compliance.

Process and CEMS mercury analyzers

Continuous monitoring of mercury in stack emissions for incinerator operators to meet BAT-AELs and control Hg emissions. Hg process monitoring enables precise adjustment of neutralizer injection, vital in reducing pollutant concentrations and adhering to regulatory standards.

Raw gas, stack emission gas monitors

Certified and approved gas CEMS for compliance with stack emission regulations (ELVs), online monitoring of raw gases for combustion optimization, fuel cost savings and precise adjustment of pollutant absorber/neutralizer injection (SCR, SNCR, DeNOx, FGD) to reduce costs and emissions of pollutants.

Raw gas, stack emission gas monitors

Certified and approved gas CEMS for compliance with stack emission regulations (ELVs), online monitoring of raw gases for combustion optimization, fuel cost savings and precise adjustment of pollutant absorber/neutralizer injection (SCR, SNCR, DeNOx, FGD) to reduce costs and emissions of pollutants.

CO2 purity analyzers for CCS

Using trace gas analysis for purity control in carbon capture and storage (CCS) ensures high CO2 quality, preventing pipeline corrosion and enhancing storage integrity. ProCeas detects impurities precisely, optimizing capture efficiency and reducing maintenance costs.

| Combustion and safety monitoring | Process and environmental monitoring |

|---|---|