Video and thermography

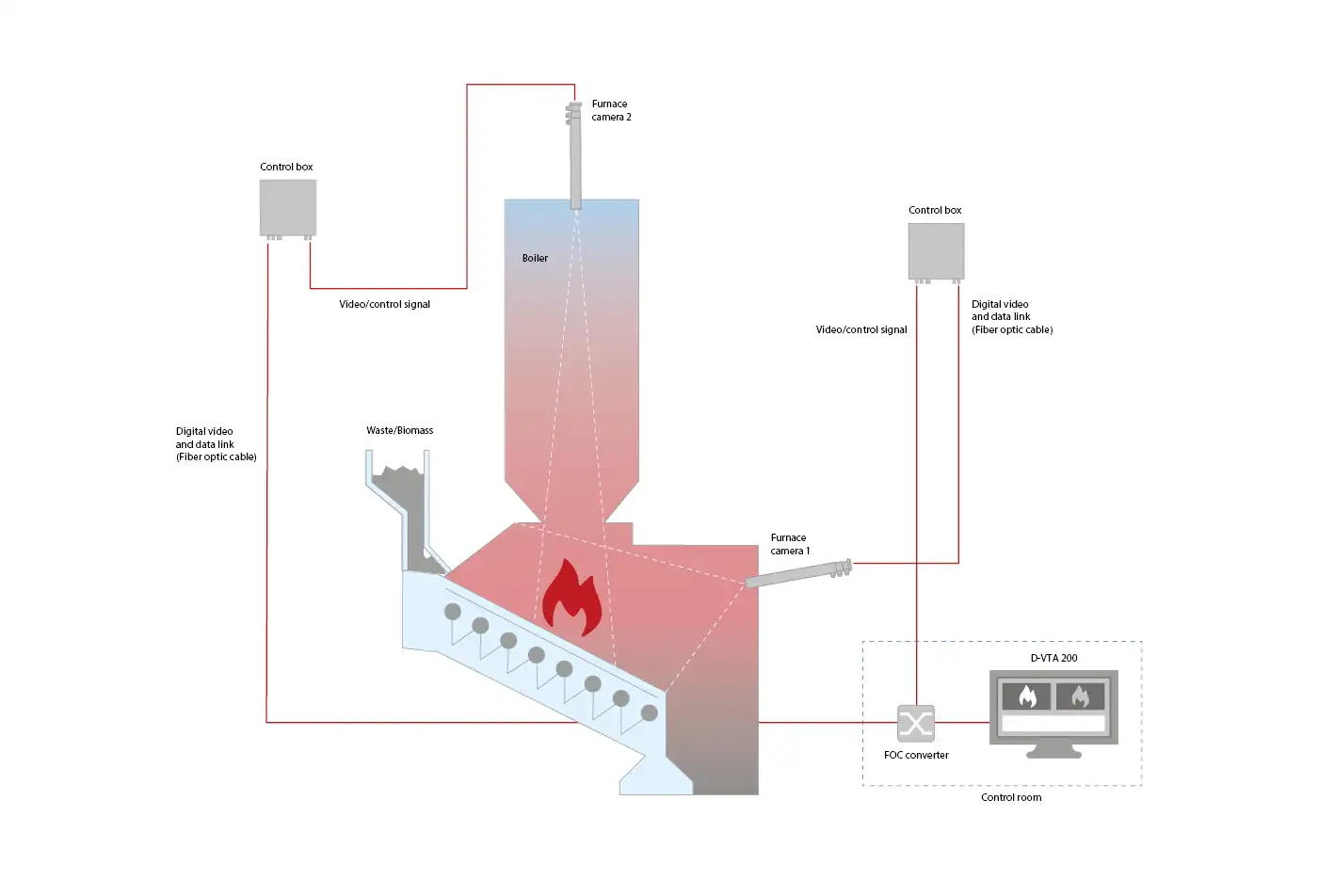

Video and thermography solutions from the DURAG GROUP visualize the combustion process at combustion plants and show the operator a detailed picture of the current combustion situation. 24/7 real-time videos from the combustion chamber and an analysis of the flame temperature distribution provide all of the information required for the best possible monitoring and control of the combustion process.

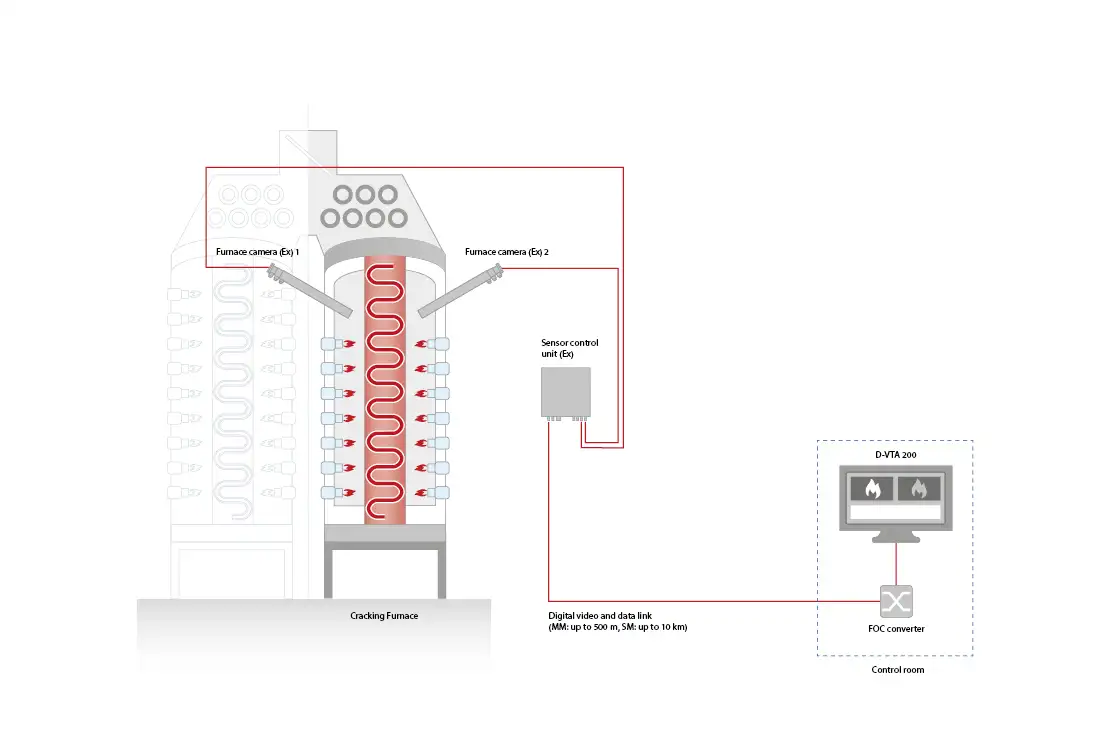

The systems are used primarily to improve efficiency and optimize processes, and industry-specific requirements are ideally met by systems specially tailored to the application: quality improvement in cement production, optimized combustion in waste incineration, reduction of wear and downtime at power plants for energy generation or avoidance of tube ruptures in cracking furnaces in the petrochemical industry.

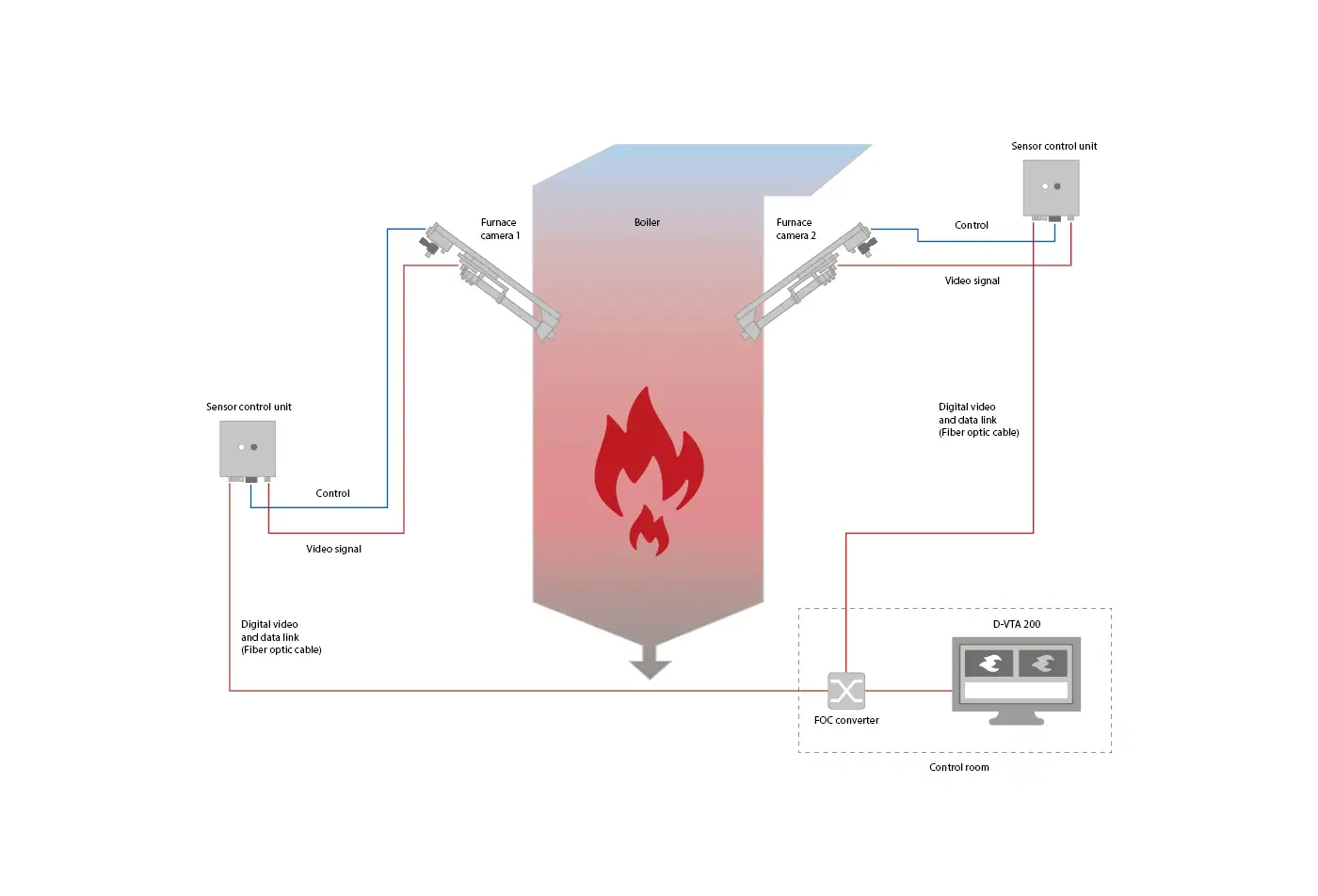

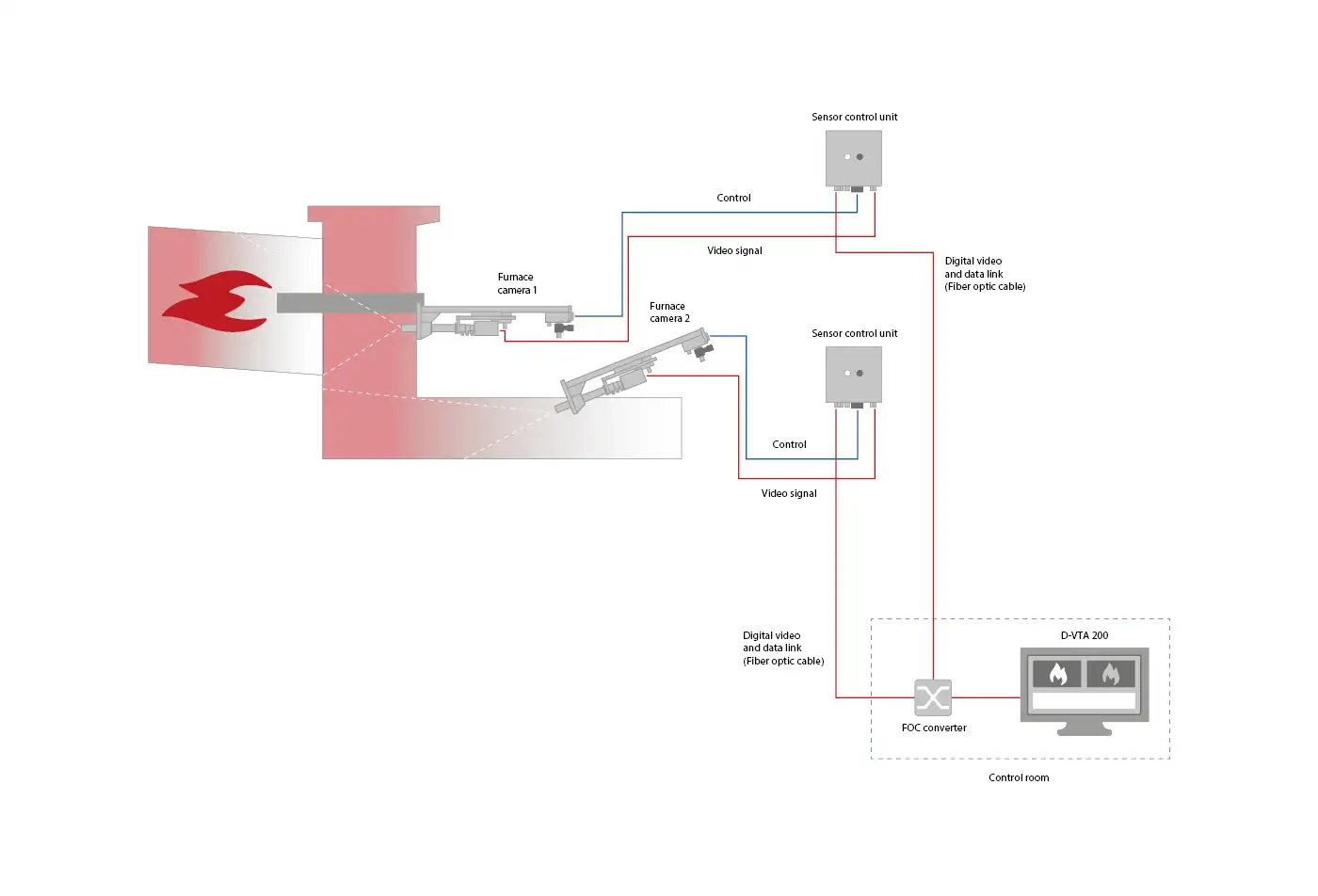

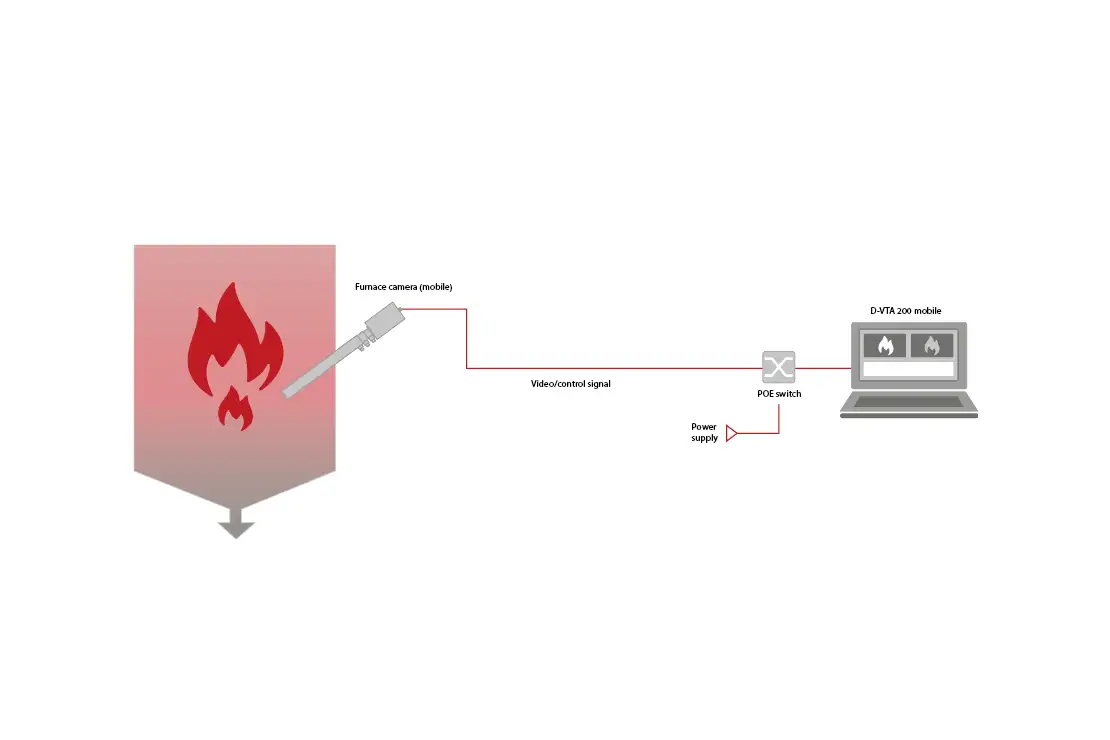

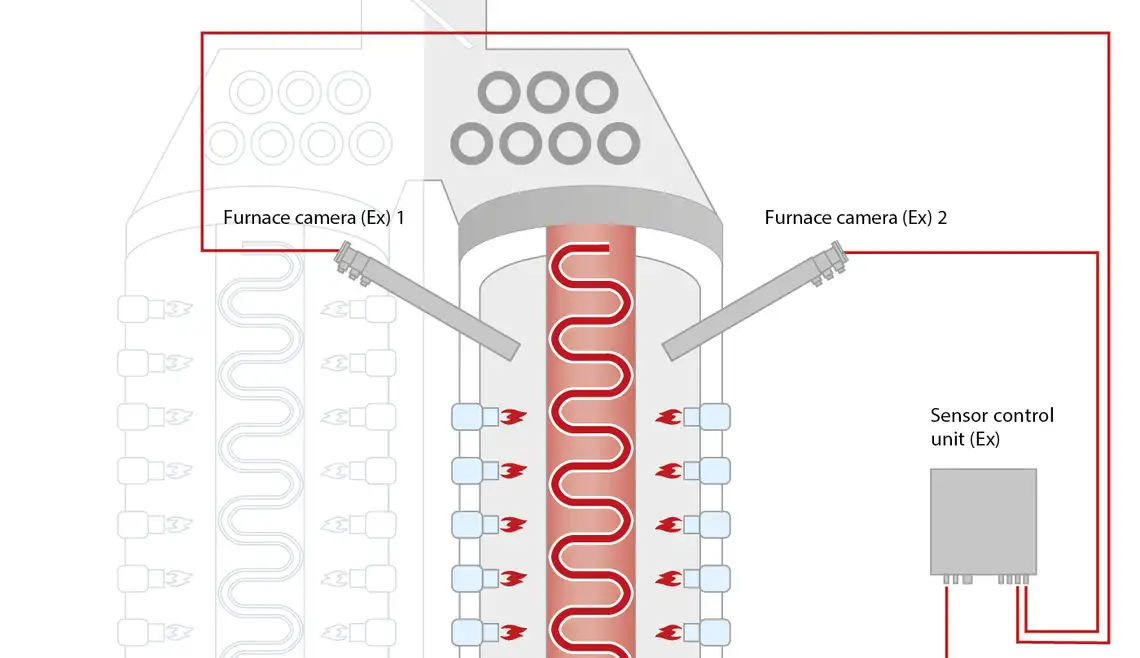

A combustion chamber video or video and thermography system always consists of a furnace camera and visualization software, although the applications and appropriate systems for them are highly industry-dependent. Depending on requirements, different air or water-cooled furnace cameras with or without a retraction unit can be combined with application-specific software modules.

Video and thermography systems

Our video and thermography systems are systems specially tailored to the application that ideally meet industry-specific needs, such as quality improvement in cement production, optimized combustion in waste incineration, reduction of wear and downtime at power plants for energy generation or avoidance of tube ruptures in cracking furnaces in the petrochemical industry. The appropriate air or water-cooled furnace cameras with or without a retraction unit are combined with our video and thermography software and the corresponding application-specific software modules.

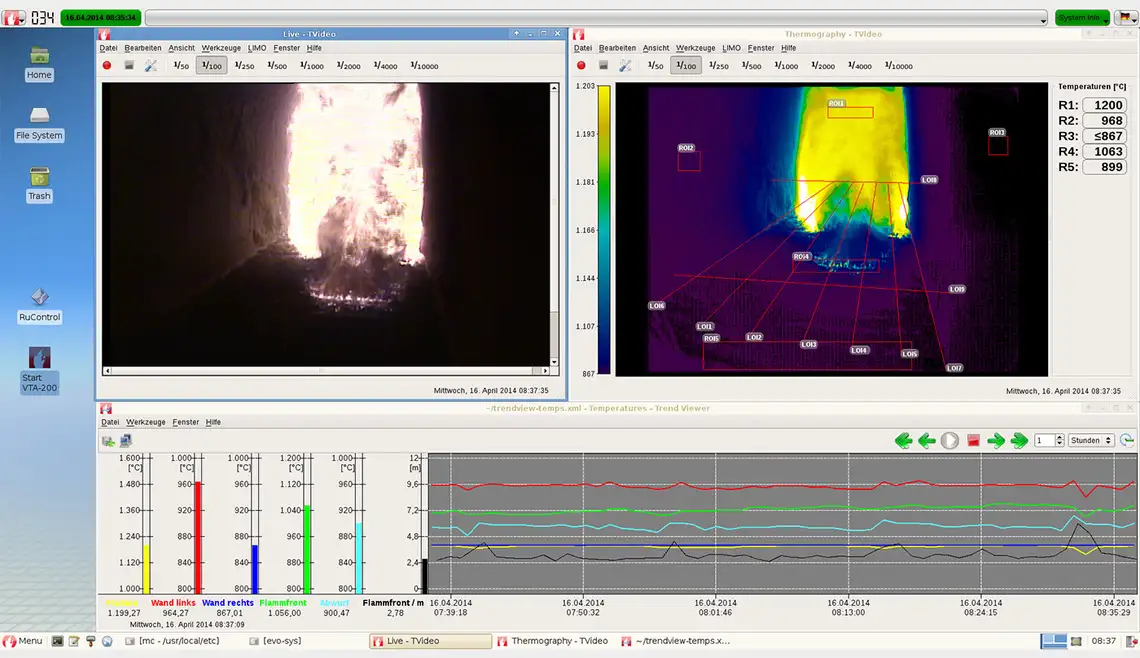

Video and thermography software

Our video and thermography software can be used in conjunction with all digital DURAG furnace cameras and can be expanded with additional modules. For example, our D‑SIP V video system can be easily replaced with a D‑VTA 200 video and thermography system at a later date, and the D‑VTA 200 basic software can be expanded later with various software modules for different applications.

As part of the D‑VTA 200 system, the thermography software calculates the temperature distribution from the video image like an optical pyrometer for each pixel. Measurement points (ROIs) can be freely defined in the temperature image and their values can be transferred to the plant control system via digital interfaces.

Furnace cameras

Our furnace cameras penetrate through the furnace or boiler wall into the combustion chamber to provide a wide view of the process and combustion. They can be remotely controlled with our video and thermography software, are air or water-cooled and suitable for extreme temperatures of up to 2,000 °C. Our special lenses with a diameter of 40 mm and the integrated digital cameras ensure brilliant live-videos. For safe operation, we offer special flanges with a protective tube for fixed installation or an optional pneumatic retraction unit that moves the camera out of the hot area if there is insufficient cooling.