- Solutions

- Combustion and Safety Monitoring

- Industrial Burner Systems

Industrial burner systems for efficient and safe combustion

Industrial burner systems from the DURAG GROUP are used in a wide variety of thermal processes, including for energy generation, in the (petro)chemical industry, steel industry, industrial furnaces, and also in the food industry. Possible applications here are the preheating of plant components such as pipes and containers, the heating of process furnaces or hot air generators and much more.

Versatile and reliable burner solutions for all industrial applications

Thanks to a high degree of flexibility in product design and various different burner sizes for a wide range of performance specifications with large thermal heat release control ranges, we can configure suitable burners for virtually all industrial applications, including in the area of heat generation. Our extremely reliable systems enable long operating times with minimum maintenance and comply with all applicable national and international guidelines, in particular the thermal process regulation.

In addition to purely mechanical designs for extreme ambient conditions we also offer compact versions with integrated electronics. Our gas and oil burners can be equipped with either high-voltage or high-energy igniters, as well as ionization or optical flame monitors. Furthermore, all burners are also available as explosion-protected versions.

To complete the firing system, we offer you the necessary fuel and air supply as well as the burner management system.

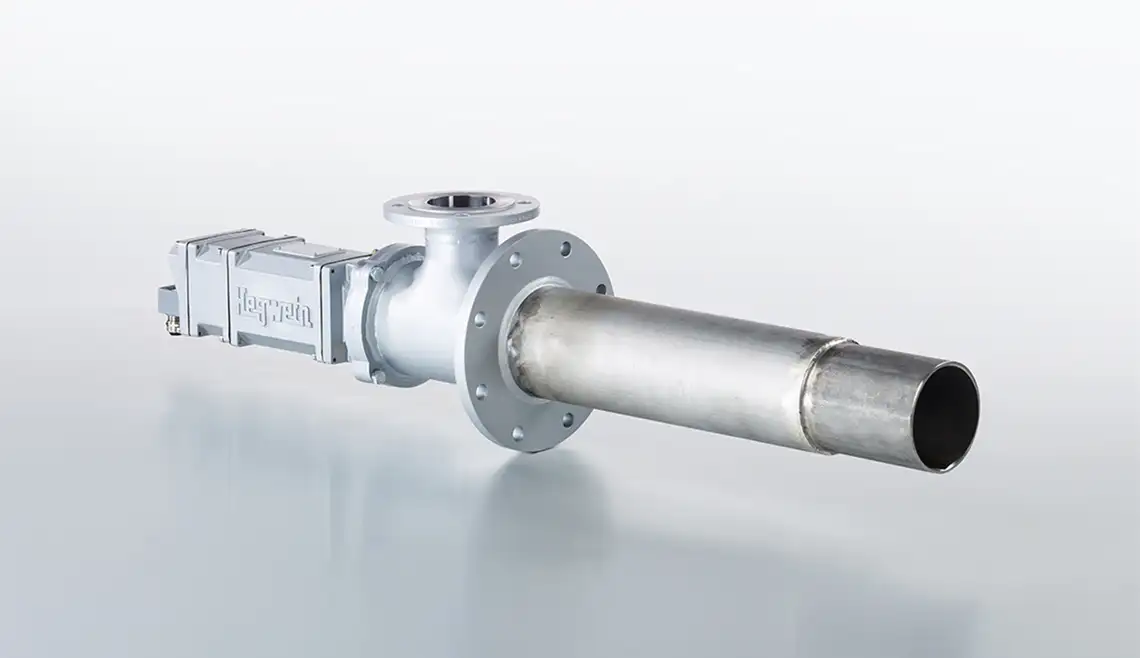

Gas burner systems for variable combustion requirements

Gas burner systems from HEGWEIN, a DURAG GROUP member, operate based on the proven swirl burner principle. In this design, the air-gas mixture is stabilized by a rotating flow, enabling uniform and clean combustion, high flame stability, and low emissions – even under fluctuating operating conditions. The special design of the mixing device at the burner head ensures reliable burner performance with a wide modulation range of up to 1:10. This mixing device can be adapted and optimized for a broad variety of gas compositions, flame shapes, and combustion chamber conditions.

As a result, the gas burners offer high flexibility and are suitable for a wide range of applications, including thermal processes in the chemical and petrochemical industries, power plants, industrial furnaces, hot gas generators, and reactors, in both continuous and intermittent operation. To ensure stable and safe combustion, integrated components such as ignition burners, flame monitoring systems, burner control units, and optional ignition transformers are used.

HEGWEIN gas burners cover output ranges from 15 kW to 4.5 MW and are available in various configurations for modulating, single-stage, or multi-stage operation. The systems are certified for use in hazardous areas, meeting the requirements for Zone 1/21 and Zone 2/22 according to ATEX, IECEx, FM-Ex, PESO, KCs, and EAC-Ex standards. These certifications ensure the highest safety standards, allowing the burners to operate safely in environments with potentially explosive gas or dust atmospheres.

| Heat release [kW] | 15 | 35 | 85 | 200 | 350 | 800 | 2,000 | 3,200 | 4,500 |

|---|---|---|---|---|---|---|---|---|---|

| Diameter [mm] | |||||||||

| 35 | P | ||||||||

| 50 | 0 | ||||||||

| 70 | 1 | ||||||||

| 88,9 | 2 | ||||||||

| 133 | 3 | ||||||||

| 159 | 4 | ||||||||

| 219 | 5 | ||||||||

| 273 | 6 | ||||||||

| 325 | 7 |

Learn more about our customized and application-specific special solutions here.

Oil burners for reliable operation with wide control range

HEGWEIN oil burners operate based on the principle of compressed air or oil pressure atomization in the form of swirl or vortex burners. In this process, the liquid fuel is finely atomized by means of compressed air, ensuring efficient mixing with combustion air. This results in a stable flame, high combustion efficiency, and reduced emissions, making these burners particularly suitable for demanding industrial applications.

Thanks to their flexible design, the oil burners can be operated with a wide range of liquid fuels, including light fuel oil, diesel, marine diesel, and biogenic or alternative oils. The specially engineered mixing device at the burner head can be adapted and optimized for various fuel properties (e.g., calorific value, viscosity), flame shapes, and combustion chamber conditions. This ensures reliable and efficient burner operation – even under fluctuating process requirements.

Typical applications include chemical and petrochemical plants, thermal process systems, and power plants. The compact, modular construction of our burners allows easy integration into existing systems and enables customized solutions for specific plant requirements.

To guarantee safe and stable operation, our oil burners are equipped with integrated ignition systems such as high-voltage ignition transformers or high-energy ignition devices. Flame monitoring is carried out using ionization flame detectors and optional optical flame monitors. In addition, an (integrated) burner control unit enables precise regulation and monitoring of the combustion process.

HEGWEIN oil burners cover a performance range from 150 kW to 6 MW and are available in various configurations for single-stage, multi-stage, or modulating operation. For use in hazardous areas, the burners are certified according to ATEX, IECEx, and FM-Ex standards, ensuring maximum operational safety.

Why choose HEGWEIN as your industrial burner manufacturer?

With over 75 years of experience, HEGWEIN stands for innovation, precision, and reliability in industrial burner technology. As part of the DURAG GROUP, HEGWEIN combines long-standing technical expertise with a global support network to deliver burner systems that meet the highest standards of safety, efficiency, and environmental compliance.

HEGWEIN offers a wide portfolio of gas and oil burners using advanced swirl (vortex) burner technology, designed for optimal combustion and reduced emissions. All products are engineered to comply with current and local regulations, including ATEX and IECEx certifications for hazardous area applications.

What sets HEGWEIN apart is the ability to provide both standardized solutions and highly customized systems tailored to specific industrial requirements. Whether for chemical processing, petrochemical applications, power generation, or thermal process systems, HEGWEIN burners are built to integrate seamlessly into new or existing installations.

Your benefits include:

- Proven performance and long service life

- Wide modulation ranges and fuel flexibility (including alternative and low-calorific fuels)

- Compact, modular designs for easy integration

- Comprehensive safety systems with reliable flame monitoring and ignition components

- Expert engineering support and long-term spare parts availability

Choosing HEGWEIN means choosing a partner who understands complex industrial combustion needs – and delivers solutions built to perform.