LaserCEM

Multi-gas monitoring system

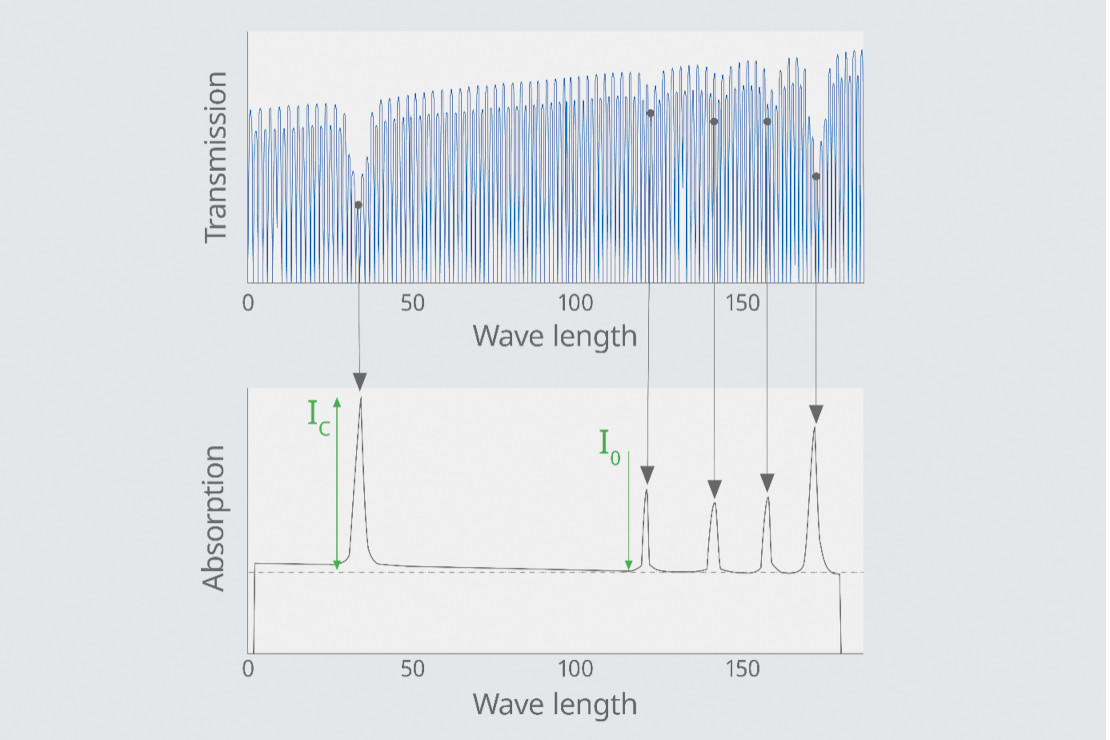

The LaserCEM® is a turnkey multi-gas stack emissions monitor for environmental compliance, using two patented technologies: OFCEAS® (Optical Feedback Cavity Enhanced Absorption Spectroscopy) and LPS® (Low Pressure Sampling).

The combination of OFCEAS® and LPS® technologies enables high spectral analysis that is interference-free, fast, and highly accurate, whatever the gas matrix to be analyzed. Its Low Pressure Sampling makes the LaserCEM® adapted to a wide range of applications without the need to heat or dry the sample prior to analysis, considerably reducing the risk of pollutants interferences or losses, as well as installation, operating and maintenance costs.

US-EPA capable, QAL1 certified and fully pre-calibrated, the LaserCEM® continuous multigas analyzer is the perfect choice for CEMS applications.

Technology: Optical Feedback Cavity Enhanced Absorption Spectroscopy (OFCEAS) and Low Pressure Sampling (LPS)

Features

- The LaserCEM® can measure a wide choice of parameters with an unforeseen quality of measurement in terms of accuracy and resolution: HF, HCl, NH3, CH4, SO2, CO, CO2, NO, NO2, O2, N2O, H2S, CHOH, H2O…

- Double QAL1 certification (by TÜV and MCERTS) according to EN 15267 and EN 14181; incorporates the QAL3 functionalities defined by EN 14181

- Lowest certified measuring ranges for hydrogen fluoride (HF), for nitrogen monoxide (NO), and for carbon monoxide (CO)

- Direct measurement without modifying the sample

- Measurement of interferents or normalization gases (water, oxygen) with the same analyzer

- Low energy, calibration gases and compressed air consumption

- Utilizes low-pressure sampling and traced lines to prevent condensation and eliminate washout effect

- Communication, control and maintenance via Modbus, (TCP/IP, RS), analog, USB and Ethernet

COMPLIANCE & CERTIFICATIONS

Certifications

- The measurement system was tested by TÜV Rheinland Energy GmbH in accordance with the European Standards EN 15267 Part 1, 2 and 3 and is QAL1 certified according to EN 14181

- QAL3 compliance as defined by EN 14181

- Certified by MCERTS performance standards for continuous emission monitoring systems (CEMS), version 4 dated July 2018 EN15267-3:2007; QAL1 certified as defined by EN 14181: 2014 - Sira MC190347/02

Compliance with international environmental regulations, such as:

European Union:

- Directive (EU) 2024/1785 (revised IED / IED 2.0 / Livestock Rearing Emissions Directive 2024/1785)

- Industrial Emissions Directive – Directive IED 2010/75/EU

- BREF Incineration

- Large Combustion Plant Directive (LCP) 2001/80/EC

- Medium Combustion Plant Directive (MCP) 2015/2193

- Emission Trading System (EU-ETS) Directive

- Best Available Techniques (BAT) Reference Document for the Smitheries and Foundries Industry (SF BREF)

- BREF on Textiles Industry

- BREF WGC (Waste Gas Management and Treatment Systems in the Chemical Sector)

- BREF Large Volume Inorganic Chemicals

- BREF Surface Treatment Of Metals and Plastics

- Installations classées pour la protection de l'environnement (ICPE)

- Guide incinération ou co-incinération de déchets non dangereux (Guide FEDENE & GIMELEC, réalisé par la FNADE, le SNIDE et le SVDU - Révision 4 – Février 2022)

- Fiches techniques Combustion

United Kingdom:

- Clean Air Strategy for England

- Environmental Permitting Regulations

- Pollution Prevention and Control (PPC) Regulations

- Industrial Emissions Directive (IED) Transposition Regulations

United States (US-EPA):

- CEMS capable of satisfying 40 CFR Part 75, 40 CFR Part 60, in accordance with Performance Specification PS-2 (SO2, NOx), PS-3 (O2 and CO2) PS-4 (CO), PS-18 (HCl)

- Clean Air Act (CAA) and CAA Stationary Source Compliance Monitoring Strategy

- New Source Performance Standards (NSPS)

- National Emission Standards for Hazardous Air Pollutants (NESHAP)

- Mercury and Air Toxics Standards

- Title V Operating Permits

- Greenhouse Gas Standards and Guidelines for Fossil Fuel-Fired Power Plants

Canada:

- Canadian Environmental Protection Act (CEPA)

- Environmental Code of Practice for Stationary Combustion Turbines

- Canada's Air Pollutant Emissions Inventory

Australia:

- National Clean Air Agreement

- State-specific regulations (e.g. Environment Protection Act in Victoria)

China:

- Regulations on Pollutant Discharge Permit Management

- China National ETS

- Notice of the Action Plan for Continuous Improvement of Air Quality

- Emission standard of air pollutants for thermal power plants

- Emission standard of air pollutants for cement industry

- Integrated emission standard of air pollutants

India:

- Environment (Protection) Act

- CPCB and SPCB guidelines for CEMS and SPM

- Standards for Emission or Discharge of Environmental Pollutants from various Industries

- Guidelines for Continuous Emission Monitoring Systems

- ...

Benefits

- Comprehensive stack emissions management:

LaserCEM® continuous emission monitoring system combines regulatory compliance, low cost of ownership, low maintenance, high availability, and environmental responsibility to provide a comprehensive approach to your stack emissions management. - True direct extractive CEMS:

No sample pre-treatment. OFCEAS technology associated with low pressure sampling enables direct measurement and eliminates the risk of chemical adsorption, desorption, and condensation along the sampling line. Accurate measurement even in high water contents (>80%). - Low cost of ownership:

Dust filters’ replacement drastically reduced; low use of compressed air and calibration gases; very low energy consumption (80 °C temperature maintained traced sampling line compared to 180 °C required by other monitoring systems). - Easy to use, easy to report emissions:

LaserCEM® is able to analyze all kind of gases and concentration ranges. In combination with DURAG DATA SYSTEMS' emission DAHS, the D-EMS 2020, tracking ELVs and sharing emissions reports with your local authority is amazingly simple. - Evolutive, futureproofed:

Modular system, allowing for the add of new gas parameters or new ranges: you to stay fit and compliant with future regulations or stack emissions monitoring objectives.

Applications

Perfectly suitable for continuous stack emission measurements for environmental compliance in all type of industries:

- Waste to energy plants (municipal, biomedical and sludge incinerators, hazardous waste incinerators at chemical or pharmaceutical plants)

- Energy from Solid Recovered Fuels (SRF) or Refuse-derived Fuel (RDF)

- Metal industries, including steel, green steel and aluminum production or recycling

- Power generation: Hydrogen power plants, coal-fired power stations, gas turbines, biomass plants...

- Mineral processing, such as cement and gypsum, brick, tiles and glass manufacturing

- Emissions from oil and gas operations in Net Zero transitions

- Chemical industries, including fertilizer production

- Treatment and remediation of contaminated soil, Residual Hazardous Materials (RHM), contaminated water and residual material

- Refineries, including ancillary sources and non-refinery process units

- Gasification and pyrolysis processes

- Oxy-fuel combustion

- DeSOx & DeNOx, FGD emission monitoring

- Efficiency control of air pollutants abatement systems

- Low NOx and ultra-low NOx measurements

- ...

Technical Data

- Compounds and measuring ranges

- Performances

- Analyzer

- Sampling system

- Turnkey LaserCEM® cabinet

| Parameter** | Certified measuring range* | Typical maximum ranges |

|---|---|---|

| CO (mg/m3) | 0 … 75; 0 … 1,249 | 0 … 3,000 |

| CO low (mg/m3) | 0 … 30; 0 … 250 | - |

| CO2 (Vol.-%) | - | 0 … 20 |

| NO (mg/m3) | 0 … 78; 0 … 150; 0 … 2,008 | 0 … 3,000 |

| NO2 (mg/m3) | 0 … 40; 0 … 100 | 0 … 2,000 |

| N2O (mg/m3) | - | 0 … 500 |

| HF (mg/m3) | 0 … 1.5; 0 … 10 | 0 … 100 |

| SO2 (mg/m3) | 0 … 75; 0 … 2,858 | 0 … 5,000 |

| HCl (mg/m3) | 0 … 15; 0 … 98 | 0 … 150 |

| NH3 (mg/m3) | 0 … 15; 0 … 45; 0 … 76 | 0 … 500 |

| CH4 (mg/m3) | 0 … 5; 0 … 20 | 0 … 500 |

| O2 (Vol.-%) | 0 … 21 | 0 … 25 |

| H2O (Vol.-%) | 0 … 30; 0 … 40 | 0 … 60 |

| H2S (mg/m3) | - | 0 … 100; 0 … 7,500 |

| CHOH (mg/m3) | - | 0 … 5; 0 … 30 |

| TOCs by FID | On request | On request |

* Certification in accordance with EN 15267‑3, QAL1 by TÜV + MCERTs

** Concentrations based on standard conditions 1,013.25 hPa and 0 °C

| Linearity | < 2% range |

|---|---|

| Repeatability | < 1% range |

| Response time | < 200 s all gases |

| Drift zero/span | < 3.0% all gases; O2 < 0.2 vol-% |

| Power supply | 110 … 230 VAC, 50 … 60 Hz, 150 VA + 10 to 45 VA/m of sampling line (consumption) |

|---|---|

| Compressed air supply | Dust free, oil free, dry, at ambient temperature 3 barg pressure at max 5.5 l/min flow, required only in maintenance mode |

| Ambient conditions | Temperature: +5 … +40 °CHumidity: 10 … 90% relative humidity, non-condensing |

| Communication interfaces | USB ports, modbus TCP, RS232, RS485 (RJ45), VGA, 4 … 20 mARemote access via Ethernet |

| Technology | Low pressure sampling (LPS®) |

|---|---|

| Sampling line | Function of the ambient temperature, unheated sampling line or traced line temperature maintained at max 80 °C; maximum length 150 m |

| Sampling probe | Includes filter and sonic nozzleMaterial: Inconel 600, other materials on requestLength: variable, tailor-made |

| Process connection | DN65 PN16 flange, stainless steel (316L) |

| Sampling box | Dimensions (H x W x D): 44 x 40 x 18 cmDegree of protection: IP65 |

| Flue gas | Temperature: +5 … +600 °CAbsolute humidity: 0 … 80% vol., higher water content on request |

| Dimensions (H x W x D) | 24U: 134 x 60 x 91 cm38U: 183 x 60 x 80 cm |

|---|

Accessories

- Mandatory

- Optional

| Sampling probe |

| Sampling line |

| Pumping system |

| Integration in cabinet |

| Air conditioning system |

| Analog outputs |

| QAL3 module for zero and span calibration |