- Solutions

- References and Case Studies

- Combustion optimization in biomass grate firing with video and thermography

Combustion optimization in biomass grate firing with video and thermography system

West Fraser is a leading manufacturer of oriented strand board (OSB) and operates biomass grate furnaces at 17 locations worldwide. To make optimum use of the fuel used, the company has been gradually equipping plants in Canada and the USA with video and thermography solutions from the DURAG GROUP since 2018. Find out here how West Fraser has significantly increased the efficiency of its plants and download the white paper on the project for more details.

At a glance

|

End customer: West Fraser |

Detailed visualization of the combustion process in grate furnaces

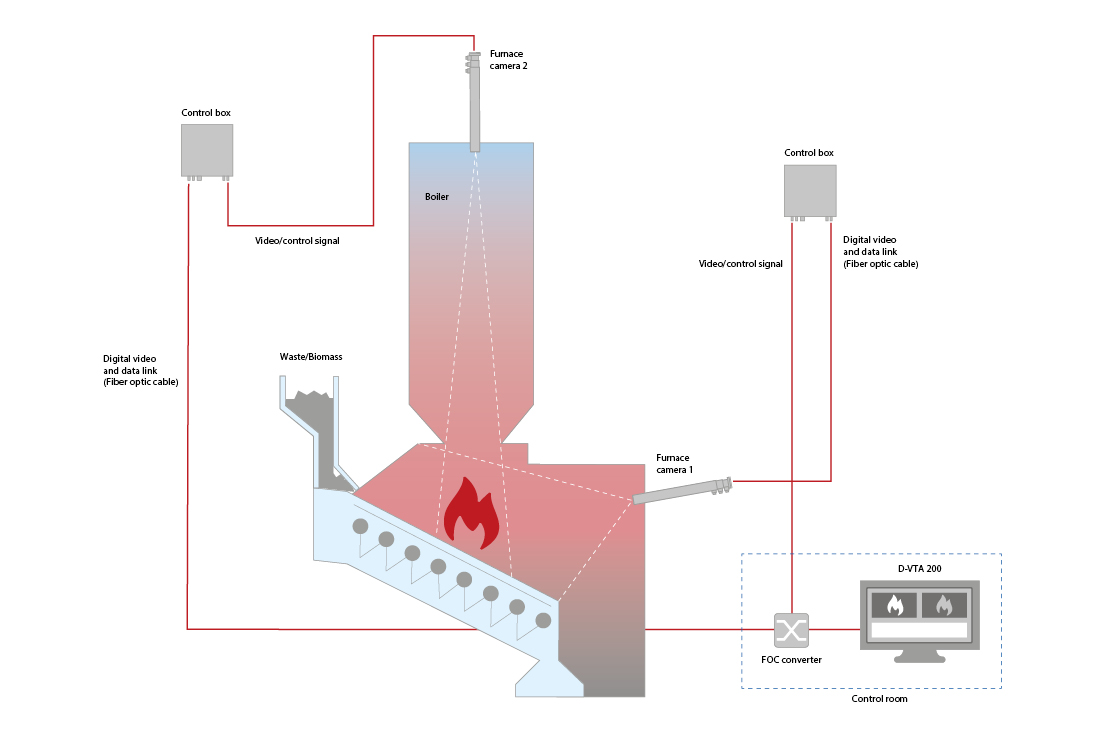

The DURAG GROUP's video and thermography solutions offer detailed visualization of the combustion process in combustion plants. With 24/7 real-time videos from the combustion chamber and an analysis of the flame temperature distribution, operators receive all the information they need to effectively monitor and control the combustion process.

To optimize combustion for West Fraser at the Grande Prairie plant in Alberta (Canada), a furnace camera with thermography and flame front determination was initially installed on two production lines in 2018. Due to convincing results, West Fraser equipped other OSB plants in Chambord, Quebec, and Allendale, South Carolina, with video and thermography systems from DURAG in the following years.

Better results thanks to water-cooled furnace camera with retraction unit

All West Fraser installations were equipped with water-cooled D-FS2 furnace cameras with retraction unit and offer a particularly wide viewing angle of 120° diagonally. For the installation in Grande Prairie, Alberta, a furnace camera with a wide-angle endoscope was specially developed. The enlarged aperture angle made it possible to monitor the entire grate with one furnace camera and to keep an eye on all parts of the grate required for automation. Another advantage of the video and thermography solution from DURAG is that the furnace camera can be moved into the combustion chamber. This significantly reduces the effort required for maintenance and cleaning.

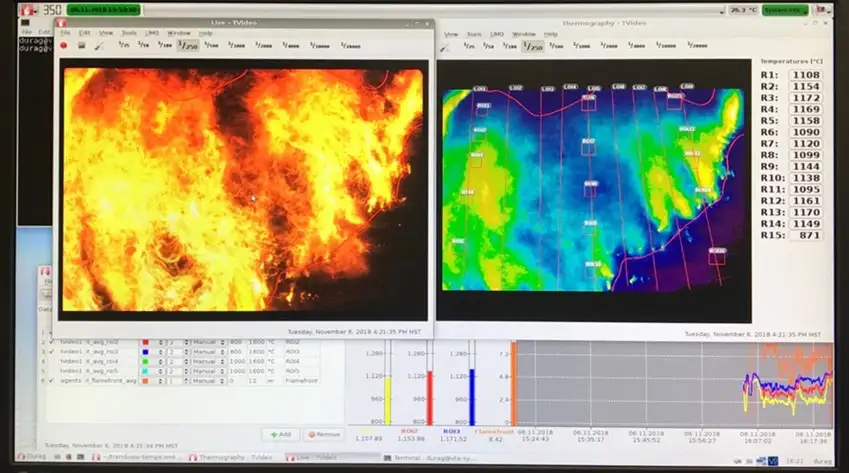

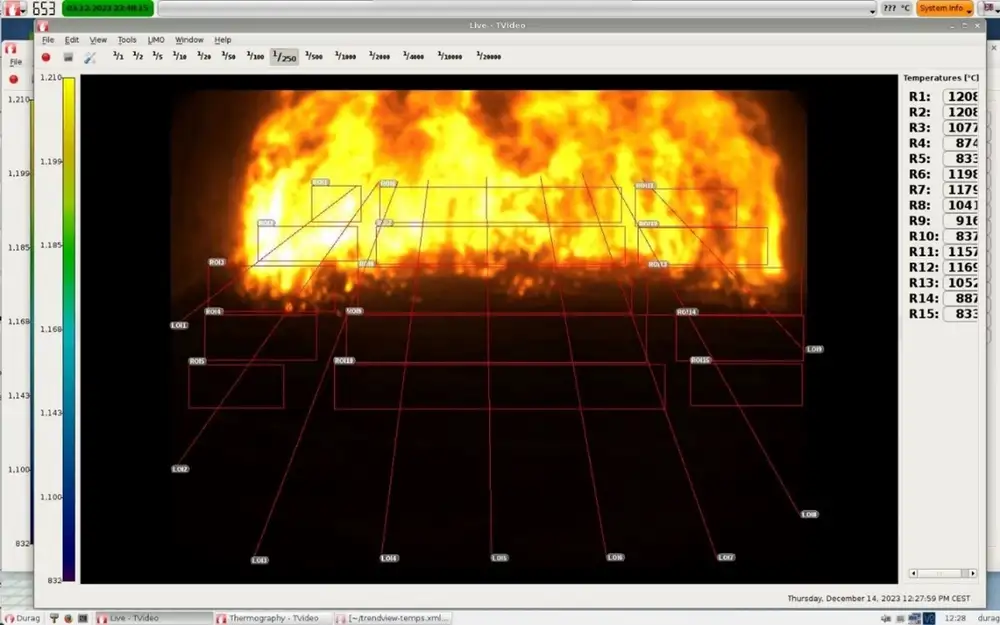

The first image shows the video and thermographic image in Grande Prairie, Alberta, without optimization. The asymmetrical distribution of the fire is clearly visible. The next image shows the video image after optimization.

Combustion efficiency massively increased by video thermography

At the plant in Grande Prairie, Alberta, the video and thermography system from DURAG has increased the degree of drying of the wood chips from 80% to over 90%. The system has also proven to be very reliable and easy to maintain and allows West Fraser to operate its plants largely independently of the knowledge and experience of the operators.

Detailed information on optimizing combustion in West Fraser's biomass grate furnaces can be found in our white paper.