Product Filter

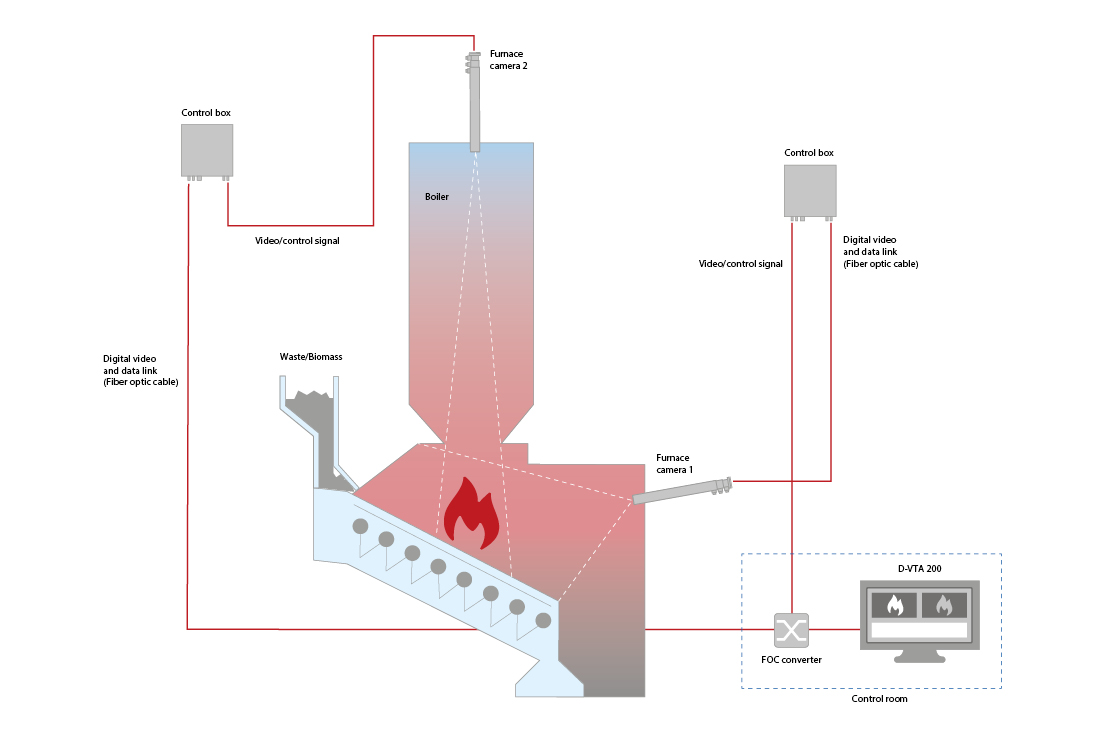

D-VTA 200 for grate firing

Video and thermography system

Video and thermography system for grate fired furnaces for monitoring the out burning zone on the grate. Used for automated combustion control and to optimize SNCR injection, saving costs and reducing wear.

Functionality: Spatial and temporal analysis of radiation images and videos

Features

- Brilliant 24/7 live videos from the out burning zone and the combustion above the grate in the boiler

- Flame Front for monitoring the out burning zone and as an optimization aid for the combustion control

- Flame Profile for determining the temperature distribution over the grate and in the boiler as an optimization aid for ammonia injection in plants with SNCR

- Digital data transmission to the process control system (e.g. Modbus TCP, Profibus)

Benefits

- Improved combustion efficiency through optimization of combustion control using Flame Front and the temperatures from the burnout zone

- Increase sales by burning more waste

- Cost reduction through less downtime and avoidance of excessive wear on the grate

- Cost reduction through lower ammonia consumption in systems with SNCR

Applications

- Visual and thermal monitoring of the burnout zone in grate fired furnaces for waste or biomass incineration

- Monitoring of the combustion above the grate and in the boiler to optimize the combustion and, if necessary, the ammonia injection in plants with SNCR

Technical Data

- Technical data

| Brief product description | Systems with retraction unit or fixed installationWater- or air-cooled systemsOne or two combustion chamber cameras in one system |

|---|---|

| Field of view | Ultra-wide angle (D-FS2 only): 120°, 94°, 72° (diagonal, horizontal, vertical)Wide angle: 90°, 72°, 54° (diagonal, horizontal, vertical)Standard: 60°, 48°, 36° (diagonal, horizontal, vertical)Zoom: 30°, 24°, 18° (diagonal, horizontal, vertical) |